Screens & Feeders

Optimizing Material Flow for Enhanced Productivity

At MEGAMAK, we offer a comprehensive range of screens and feeders engineered to ensure consistent material flow, efficient separation, and seamless integration with crushing and screening plants. Our equipment is designed to handle a variety of materials, from fine aggregates to coarse, abrasive substances, ensuring optimal performance in diverse operational conditions.

Our Screens

Grizzly Screens

MGS Series

MEGAMAK Grizzly Screens are installed at the primary stage to separate oversized material, ensuring efficient feeding to crushers. Key features include:

-

Heavy-Duty Construction: Built to handle coarse materials and harsh operating conditions.

-

Adjustable Grizzly Bar Spacing: Allows customization to suit specific material characteristics.

-

Efficient Scalping: Effectively removes fines and oversized material, enhancing downstream equipment performance.

Horizontal Screens

MH Series

Our Horizontal Screens are designed for fine material screening, offering precise separation with minimal moisture content. Features include:

-

Low Vibration Stroke: Provides gentle material handling, reducing degradation.

-

Compact Design: Ideal for installations with limited space.

-

Efficient Performance: Delivers consistent screening results in fine material applications.

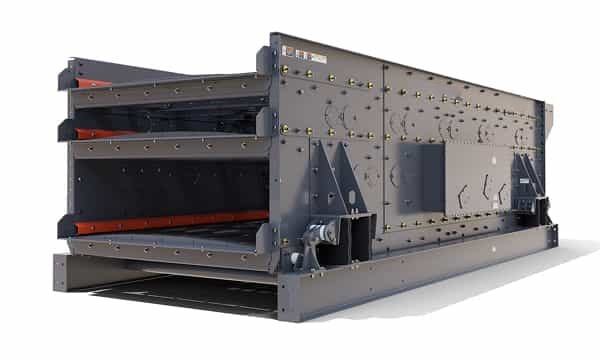

Inclined Screens

MS Series

MEGAMAK Inclined Screens are engineered for high-capacity screening, delivering accurate material separation across multiple decks. Key specifications include:

-

Multiple Deck Configurations: Available in 2, 3, and 4-deck models to suit various screening needs.

-

High Vibration Stroke: Ensures efficient material stratification and separation.

-

Durable Construction: Built with high-quality materials to withstand demanding applications

Our Feeders

Vibrating Feeders

MVF Series

MEGAMAK Vibrating Feeders are designed for high-capacity feeding, particularly in secondary and tertiary applications. These feeders provide a steady material flow, ensuring consistent feeding to crushers and screens. Key features include:

-

High-Quality Vibro Motors: Equipped with industry-leading vibro motors, ensuring reliable long-term operation with minimal maintenance.

-

Adjustable Feed Capacity: Frequency converters allow for easy adjustment of feed rates to match operational requirements.

-

Robust Construction: Built to withstand the rigors of heavy-duty applications, ensuring longevity and durability.

Grizzly Feeders

MGF Series

Our Grizzly Feeders are installed under primary hoppers to ensure a consistent feed to primary crushers. They efficiently screen out undersized material, reducing crusher load and wear while significantly lowering operating costs. Features include:

-

Robust Frame and Components: Fully welded body with heat-treated S355Jr steel base plate and 12 mm side plates for enhanced durability.

-

High-Quality Vibro Motors: Equipped with Oli Vibro motors, known for their reliability and low maintenance requirements.

-

Adjustable Feed Capacity: Frequency converters allow for easy adjustment of feed rates to match operational requirements.

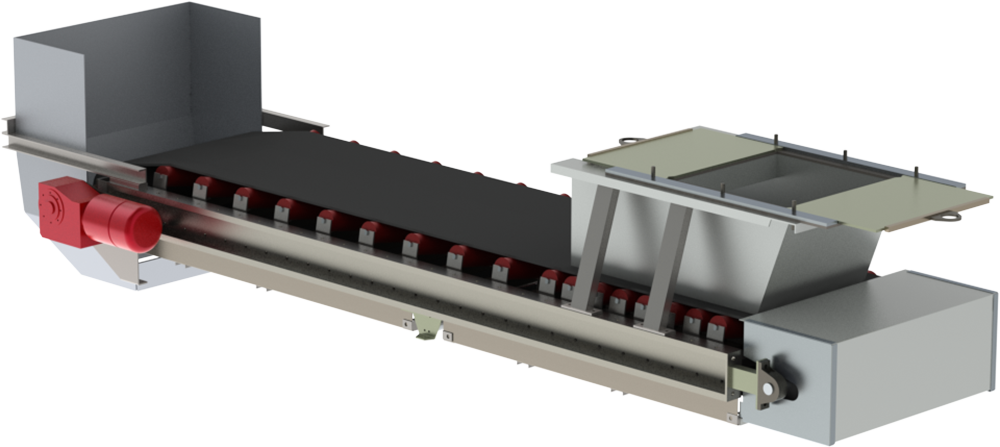

Apron Feeders

MAF Series

Our Apron Feeders are designed to handle heavy, abrasive, or lumpy materials, ensuring a consistent feed to crushers and other equipment. Features include:

-

Heavy-Duty Construction: Built to withstand the toughest materials and operating conditions.

-

Customizable Design: Can be tailored to meet specific application requirements, including varying lengths, widths, and capacities.

-

Efficient Material Handling: Ensures a steady and controlled material flow, reducing operational disruptions.

Belt Feeders

MBF Series

MEGAMAK Belt Feeders are designed for continuous material feeding, providing a steady and controlled flow of materials to crushers, screens, and other equipment. Key specifications include:

-

Capacity Range: Available models include MBF 6525, MBF 8025, and MBF 1025, catering to various capacity needs.

-

Durable Construction: Built with high-quality materials to ensure longevity and reliability in demanding applications.

-

Versatile Applications: Suitable for a wide range of materials, including aggregates, coal, and ores.

Visit our corporate site: megamak.net for other engineering solutions