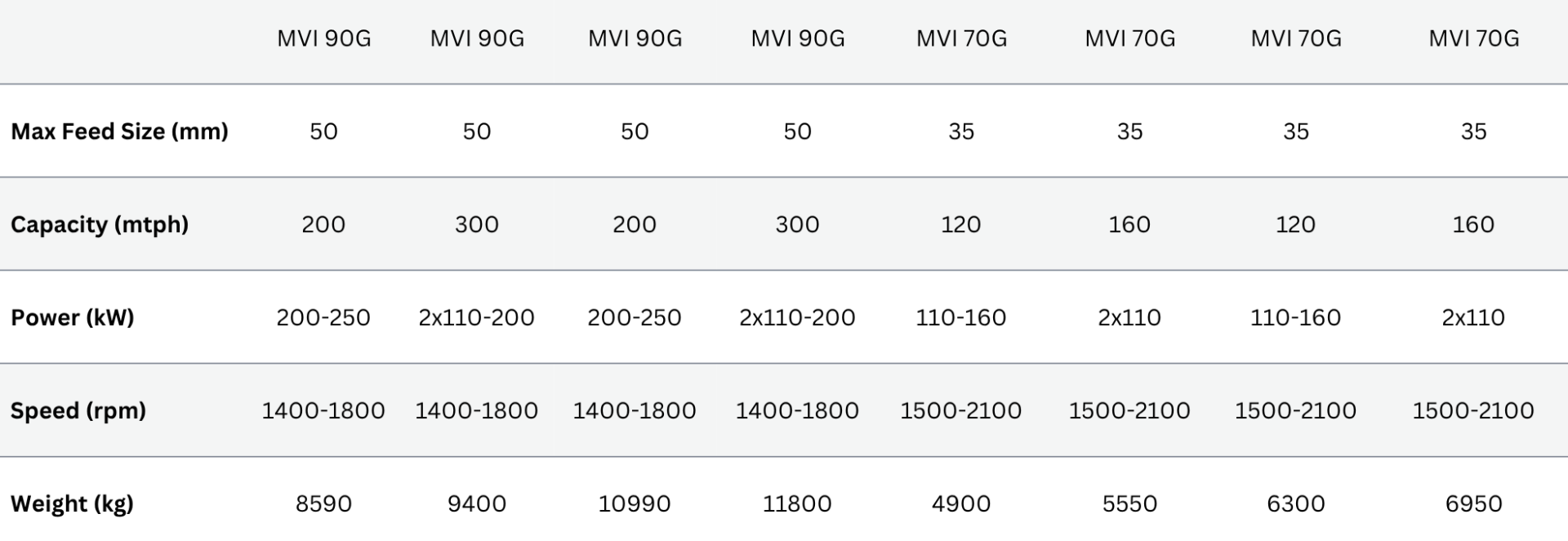

VSI Crushers

Available in open or closed rotor configurations with multiple feed options.

VSI Crushers

Megamak VSI Crushers are engineered to produce precisely shaped end products through high-speed impact and particle-on-particle crushing technology.

Designed for the final stage of the crushing process, VSI machines are ideal for manufacturing premium-quality aggregates, artificial sand, and finely shaped minerals.

By utilizing centrifugal force and optimized rotor dynamics, Megamak VSI Crushers offer outstanding control over product size, reduced wear costs, and superior performance — even in the most demanding applications.

Key Advantages

-

Superior Cubic Shaping: Achieves excellent particle shape with consistent gradation.

-

High-Speed Rotor Design: Ensures powerful impact and high reduction ratios.

-

Low Operating Costs: Minimal wear part consumption and easy maintenance.

-

Flexible Operation: Suitable for wet, dry, and semi-dry material conditions.

-

Energy Efficiency: Optimized rotor and chamber geometry for reduced power demand.

Applications

-

Final shaping in aggregate production

-

Manufactured sand (M-sand) production

-

Glass, slag, and industrial mineral processing

-

Concrete and asphalt mix preparation

-

Fine crushing of abrasive materials

Performance & Design

Megamak VSI Crushers utilize a unique rock-on-rock crushing principle that minimizes wear and improves product shape.

The high-speed rotor accelerates material into the crushing chamber, creating impact energy that fractures the rock naturally along its internal weaknesses — resulting in clean, angular, and well-graded particles.

The modular design ensures easy access for inspection and maintenance, while the adjustable cascade system allows operators to fine-tune the end product to specific requirements.

After Sales & Support

Megamak's VSI line is supported by an extensive service network, ensuring maximum uptime and consistent performance through:

-

OEM spare and wear parts supply

-

On-site rotor balancing and alignment

-

Maintenance training and technical supervision

-

Application engineering and performance optimization

Megamak — where velocity meets precision.